CNC Lathe Factory: Transforming Metal Fabrication

In the ever-evolving landscape of manufacturing, a cnc lathe factory stands at the forefront, driving innovation and efficiency in metal fabrication. At Deep Mould, we harness the power of cutting-edge technology to produce high-quality, precision-engineered components that meet the demands of various industries. Our commitment to excellence sets us apart in an increasingly competitive market.

The Importance of CNC Lathes in Modern Manufacturing

CNC (Computer Numerical Control) lathes have revolutionized the way we approach metal fabrication. These machines provide unparalleled precision and efficiency, enabling manufacturers to produce complex parts quickly and accurately. Here are several reasons why CNC lathes are essential in today’s manufacturing sector:

- Precision Engineering: CNC lathes operate on computer-generated programs, ensuring each cut and groove is executed with millimeter accuracy.

- Reduced Lead Times: With automation, CNC lathes significantly reduce the time from concept to production, allowing for faster project turnaround.

- Complex Designs: Capable of turning intricate designs into reality, CNC lathes can create shapes and profiles that traditional lathes cannot achieve.

- Consistency and Reproducibility: Once programmed, a CNC lathe can reproduce the same component thousands of times with little variation.

- Cost-Effective Manufacturing: Although the initial investment is higher, the efficiency of CNC lathes often results in lower operational costs over time.

Deep Mould: Your Trusted CNC Lathe Factory

At Deep Mould, we pride ourselves on being a leader in the manufacturing industry, particularly in CNC machining and metal fabrication. Our cnc lathe factory is equipped with state-of-the-art machines operated by highly skilled technicians who follow strict quality control protocols. Here's what you can expect when you partner with us:

State-of-the-Art Technology

Our factory utilizes the latest advancements in CNC technology, allowing us to improve efficiency and productivity. Our CNC lathes are programmed with the latest software that enables real-time adjustments and monitoring throughout the machining process. This technological edge ensures that we can respond swiftly to customer needs.

Expert Team

The backbone of any manufacturing operation is its workforce. At Deep Mould, our engineers and machinists are highly trained professionals with years of experience in the field. Their expertise allows us to tackle even the most challenging projects with confidence, ensuring that we meet and exceed our clients' expectations.

Quality Assurance

Quality is at the heart of everything we do. Our cnc lathe factory adheres to stringent quality control processes at every stage of production. From the initial design phase to the final inspection of products, we ensure that our components are manufactured to the highest standards.

Applications of CNC Lathe Manufacturing

The versatility of CNC lathes allows for their application across various industries. Here are some of the prominent sectors that benefit from our CNC lathe services:

Aerospace

The aerospace industry demands components that are lightweight and incredibly durable. Our CNC lathes can produce precision parts for aircraft engines, fuselages, and landing gear, ensuring compliance with rigorous safety standards.

Automotive

In the automotive sector, manufacturers require high-quality, reliable components for vehicles. From engine parts to transmission components, our cnc lathe factory produces precision-engineered products tailored to the specifications of our clients.

Medical Devices

The manufacturing of medical devices requires an emphasis on precision and regulation compliance. Our CNC lathes are capable of producing intricate components for surgical instruments, implants, and other medical apparatus, ensuring they meet all necessary health standards.

Electronics

In the fast-paced electronics industry, rapid prototyping and production are crucial. Our state-of-the-art CNC lathes allow for quick adjustments and high-volume production of enclosures and housings for electronic components.

The Process of CNC Lathe Machining

Understanding the CNC lathe machining process can help you appreciate the level of efficiency and quality that Deep Mould offers. Here’s a detailed breakdown of the steps involved:

Design and Prototyping

Every project begins with a design. Our team works closely with clients to understand their specific needs and translate those requirements into detailed CAD (Computer-Aided Design) drawings. Prototyping is also an essential step, allowing us to craft a sample for client approval before full-scale production begins.

Programming the CNC Lathe

Once the design is finalized, our engineers create a program that the CNC lathe will follow. This involves specifying the exact movements and operations required to shape the raw material into the desired component.

Material Selection

Choosing the right material is crucial for the end product's performance. At Deep Mould, we work with a wide variety of metals, including aluminum, steel, brass, and titanium, tailoring material selection to meet the specific needs of each project.

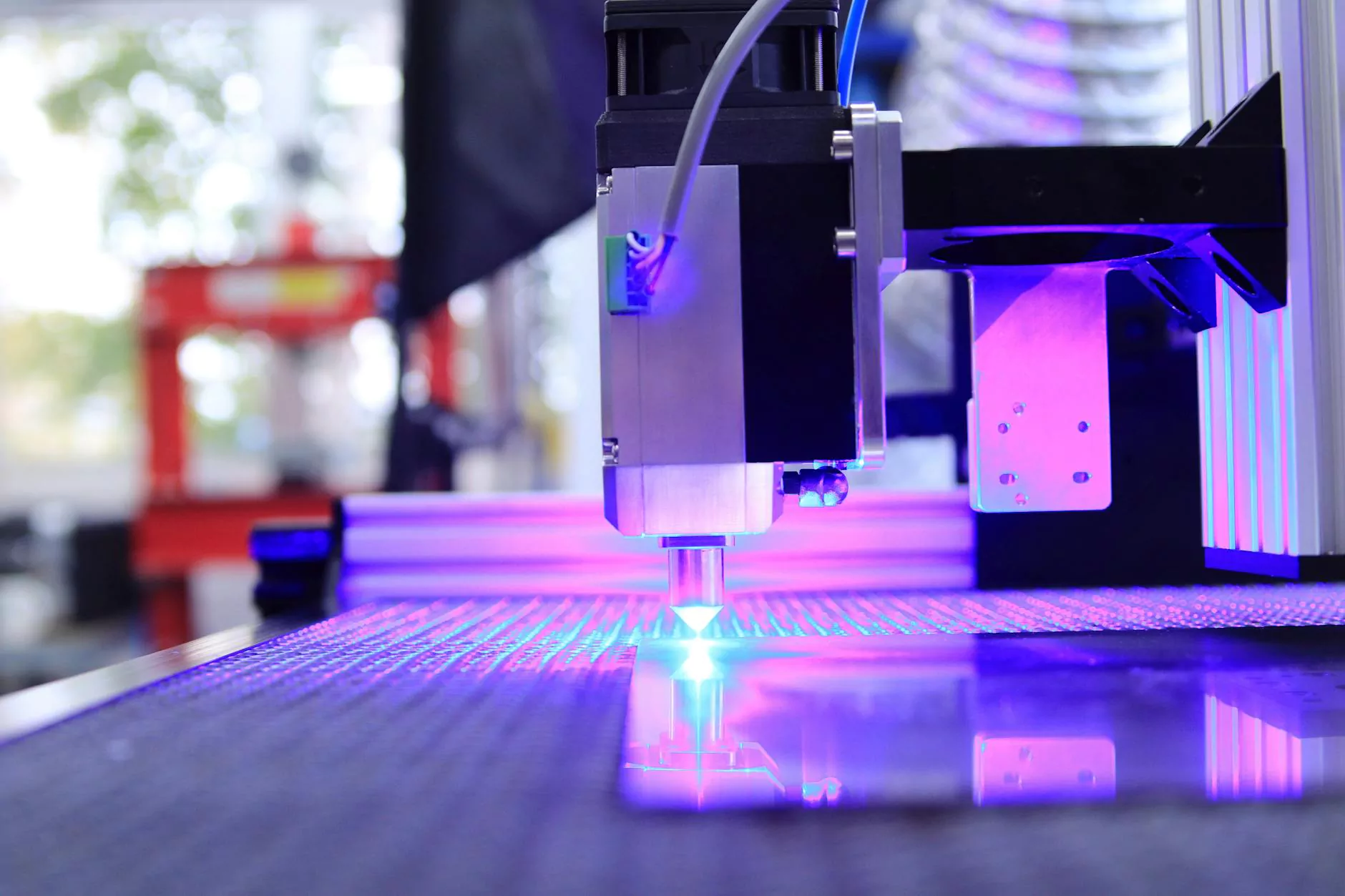

Machining Process

With everything in place, the CNC lathe begins machining. The machine cuts, shapes, and finishes the metal according to the programmed instructions. Our operators carefully monitor the process, making adjustments as needed to maintain consistency and quality.

Final Inspection

After machining, each component undergoes a rigorous quality inspection process to ensure it meets our high standards and satisfies client specifications. This step is crucial to maintaining our reputation as a leading cnc lathe factory.

Advantages of Choosing Deep Mould

When it comes to CNC lathe manufacturing, choosing the right partner can make all the difference. Here are some advantages of working with Deep Mould:

- Customization: We understand that each project has unique requirements. Our team is dedicated to providing customized solutions that meet your specific needs.

- Competitive Pricing: We offer cost-effective solutions without compromising quality, making us a preferred choice for businesses of all sizes.

- Timely Delivery: Our efficient processes ensure that we meet deadlines and deliver products on time, helping you stay on schedule.

- Comprehensive Support: From concept to completion, we offer support and guidance throughout the manufacturing process.

Future Trends in CNC Lathe Manufacturing

The CNC lathe industry is continuously evolving. As technology advances, we expect to see several trends that will shape the future of manufacturing:

Increased Automation

With advancements in robotics and AI, we anticipate that automation will play a more significant role in CNC machining. This will enhance efficiency and allow for even greater precision in the manufacturing process.

Smart Manufacturing

The integration of IoT (Internet of Things) in manufacturing processes will lead to smarter factories that can monitor equipment health and predict maintenance needs, reducing downtime and improving productivity.

Sustainable Manufacturing

As environmental concerns grow, more manufacturers will focus on sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste and energy consumption.

Conclusion: Your Partner in Metal Fabrication Success

Choosing the right cnc lathe factory is crucial for the success of your metal fabrication projects. At Deep Mould, we combine innovation, precision, and expertise to deliver top-quality components that meet your specific needs. Whether you are in aerospace, automotive, medical, or electronics, our team is ready to partner with you for your next project. Experience the difference that a dedicated and high-quality CNC lathe manufacturing service can make. Contact us today for more information!