Transforming Manufacturing with Rapid Prototyping Injection Molding

In today's fast-paced industrial landscape, businesses must continually innovate and adapt to remain competitive. One of the most transformative techniques in modern manufacturing is rapid prototyping injection molding. This advanced method not only streamlines the production process but also significantly enhances the quality of the final products. By embracing this innovative approach, companies can reduce time-to-market, optimize their designs, and ensure higher customer satisfaction.

Understanding Rapid Prototyping Injection Molding

Rapid prototyping injection molding is a technique that combines traditional injection molding practices with the speed and efficiency of rapid prototyping technology. It allows manufacturers to create prototypes and production parts quickly and cost-effectively. This process typically involves the following steps:

- Design Creation: The product design is created using CAD software (Computer-Aided Design).

- 3D Printing of Prototypes: Initial prototypes are rapidly produced using 3D printing technologies.

- Mold Fabrication: Injection molds are manufactured, often using faster techniques like CNC machining.

- Injection Molding: Thermoplastic materials are injected into the molds to create the final product.

The Benefits of Rapid Prototyping Injection Molding

The adoption of rapid prototyping injection molding presents numerous advantages for businesses, particularly for those involved in metal fabrication. Here are some of the key benefits:

1. Accelerated Time-to-Market

In today's competitive market, speed is crucial. With rapid prototyping injection molding, manufacturers can significantly reduce the time it takes to transition from design to market. The ability to quickly produce prototypes allows for immediate testing and iteration, ensuring that the final product meets market demands.

2. Cost-Effective Solutions

By minimizing the number of prototypes needed and speeding up the development process, businesses can dramatically cut costs associated with product development. The initial investment in rapid prototyping can lead to substantial savings in the long run.

3. Improved Product Quality

With rapid prototyping injection molding, manufacturers can identify design flaws early in the process, leading to a higher quality end product. The ability to test and refine designs before full-scale production ensures that only the best products hit the market.

4. Flexibility and Customization

This method allows for greater flexibility in design and customization. Manufacturers can easily make adjustments based on customer feedback, enabling them to create tailored solutions that meet specific client needs.

5. Supports Complex Geometries

Modern injection molding techniques allow for the creation of complex shapes and designs that were previously difficult or impossible to achieve. This opens up new possibilities for innovation and design in various industries.

Applications of Rapid Prototyping Injection Molding

The versatility of rapid prototyping injection molding means it can be applied across various sectors. Here are some notable applications:

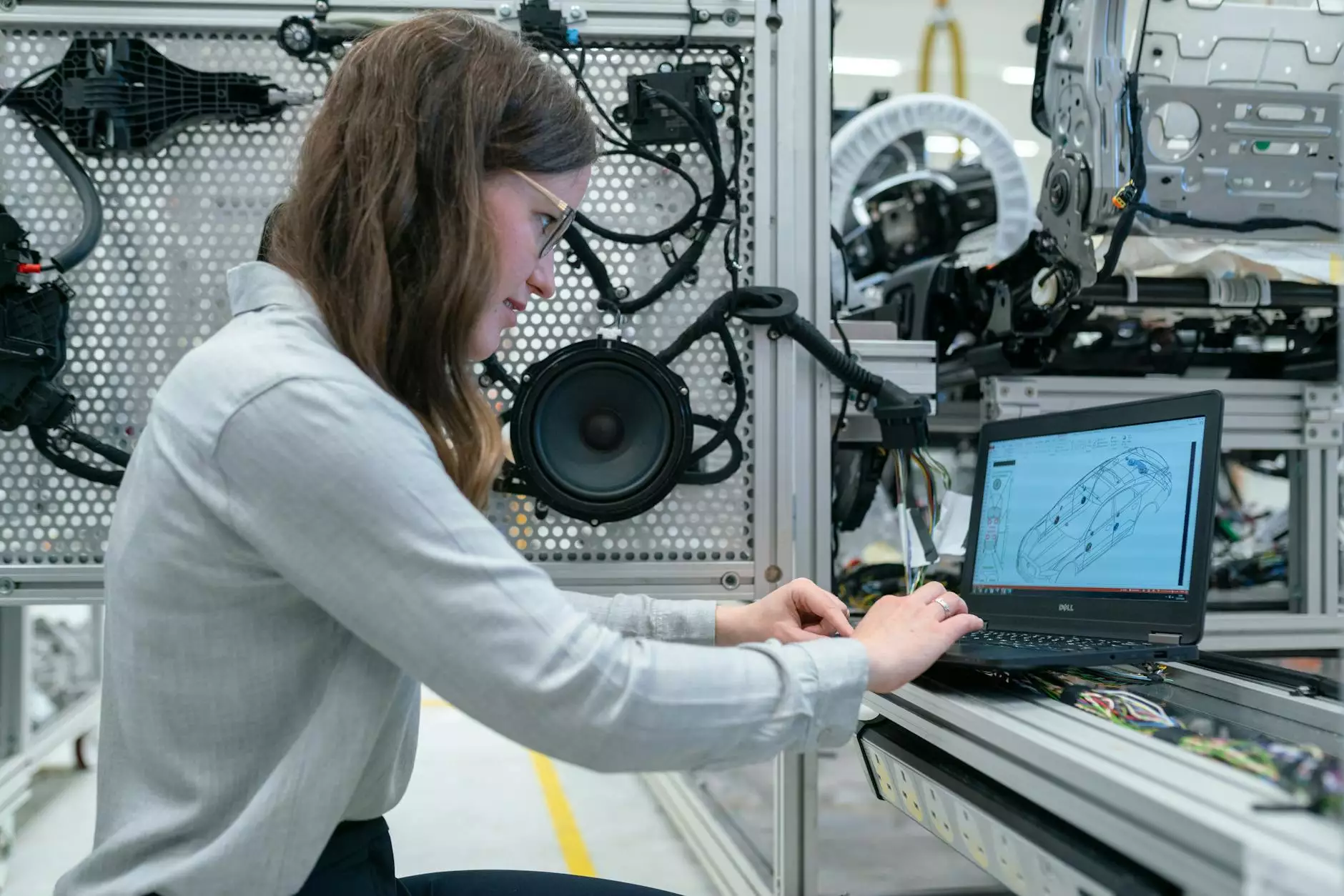

A. Automotive Industry

The automotive sector benefits immensely from rapid prototyping, allowing manufacturers to develop new parts and components with speed and accuracy. Whether it’s for prototyping dashboards or intricate engine components, this method streamlines production and enhances performance.

B. Medical Devices

In the medical field, precision and compliance with strict regulations are paramount. Rapid prototyping injection molding enables the rapid production of high-quality medical devices, from surgical tools to diagnostic equipment, ensuring they meet exacting standards.

C. Consumer Electronics

With the rapid pace of technological advancement in consumer electronics, companies need to quickly bring new products to market. Rapid prototyping injection molding allows for quick iterations and optimizations of designs, leading to innovative gadgets that meet consumer demands.

D. Aerospace

The aerospace industry relies on high-performance components that must withstand intense conditions. The ability to create durable, lightweight components through rapid prototyping can result in improved efficiency and safety in aircraft design.

Challenges and Considerations

Despite the benefits, there are challenges associated with rapid prototyping injection molding that manufacturers should be aware of:

1. Initial Cost of Equipment

The initial investment for adding rapid prototyping capabilities can be significant, particularly for small businesses. However, the long-term savings and productivity gains often outweigh these costs.

2. Material Limitations

While many materials can be used in rapid prototyping injection molding, not all materials are suitable for high-performance applications. It's essential to choose materials that can withstand the requirements of your industry.

3. Need for Skilled Personnel

To fully leverage the advantages of rapid prototyping injection molding, companies must have skilled personnel who understand both the technology and the design aspects of production.

The Future of Rapid Prototyping Injection Molding

As technology continues to evolve, the future of rapid prototyping injection molding looks brighter than ever. With advancements in materials, software, and processes, manufacturers can expect enhanced capabilities, faster speeds, and even better quality products.

"The pace of innovation is increasing, and rapid prototyping injection molding is at the forefront of this evolution. Businesses that take advantage of these revolutionary processes will gain a vital edge in their respective markets."

Why You Should Choose DeepMould.net

At DeepMould.net, we specialize in providing state-of-the-art rapid prototyping injection molding services tailored to meet the unique needs of our clients. Our experienced team is dedicated to ensuring high-quality results, timely deliveries, and exceptional customer service. Here’s why you should partner with us:

- Expertise: Our skilled professionals possess extensive knowledge in metal fabrication and injection molding techniques.

- Advanced Technology: We utilize cutting-edge technology and equipment to produce superior prototypes and production parts.

- Customization: We work closely with clients to deliver customized solutions that align with their specific requirements.

- Reliable Turnaround: Our commitment to timely service means you can count on us for quick and efficient project completion.

Conclusion

In conclusion, rapid prototyping injection molding is revolutionizing the way businesses approach manufacturing and product development. Its numerous advantages—ranging from faster time-to-market to enhanced product quality—make it an invaluable tool in the competitive landscape of modern manufacturing. By integrating this technology into their processes, companies can achieve greater efficiency, innovation, and customer satisfaction.

If you are ready to transform your production capabilities and drive your business towards success, DeepMould.net is here to assist you in navigating the exciting possibilities offered by rapid prototyping. Together, we can shape the future of manufacturing.